Proper documentation and organization of our inventory is a key components of running our restaurant efficiently. This documentation covers how to store items, the procedures, and the best practices we have in place to make inventory management smooth and effective.

This is what you will need to do:

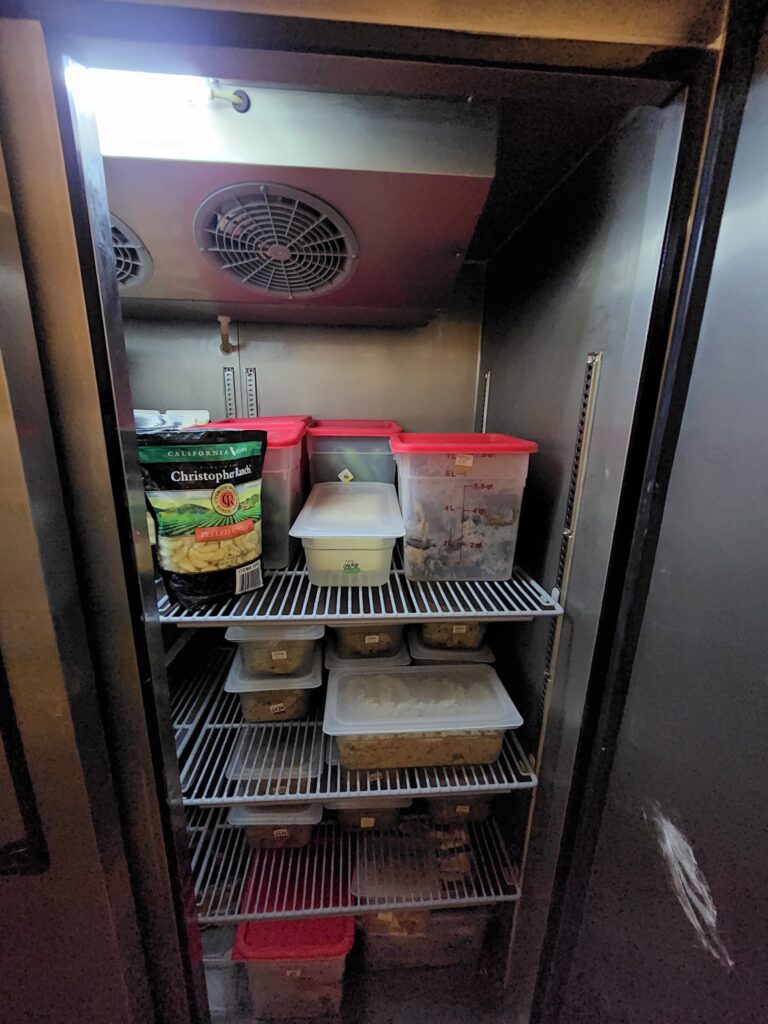

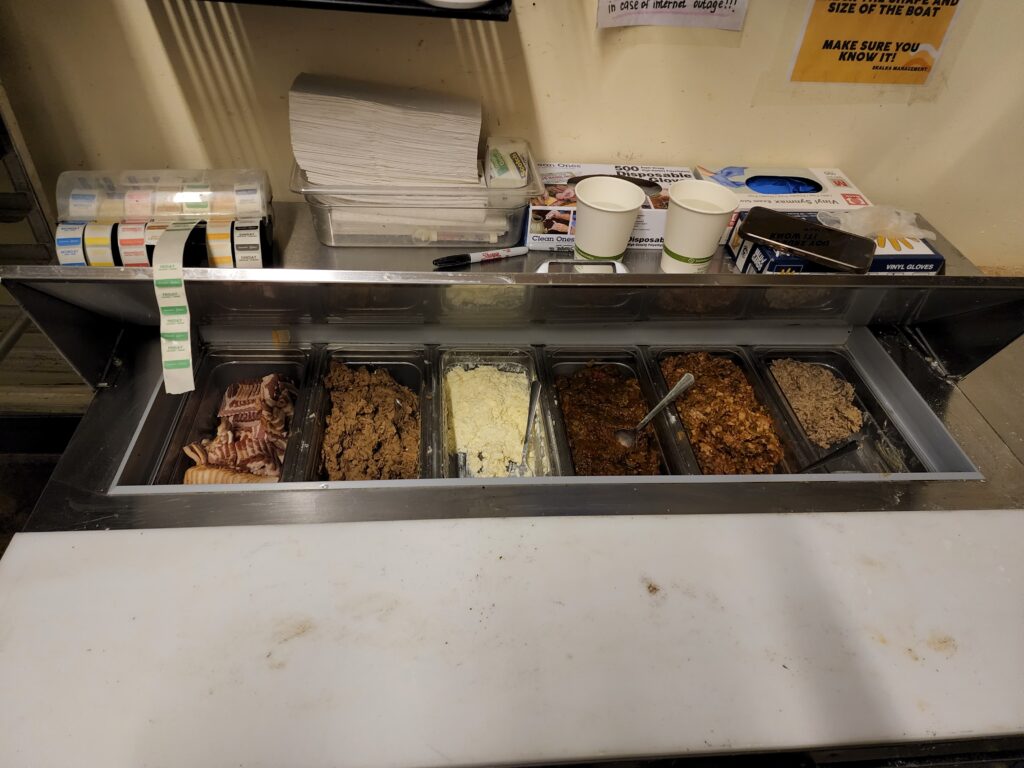

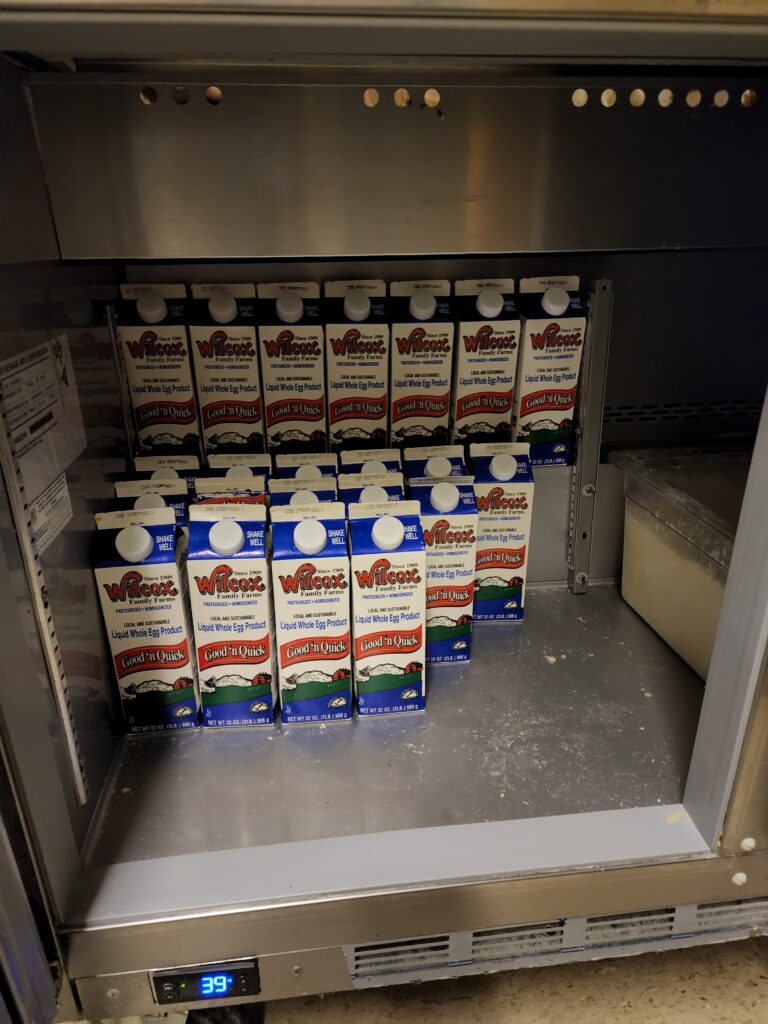

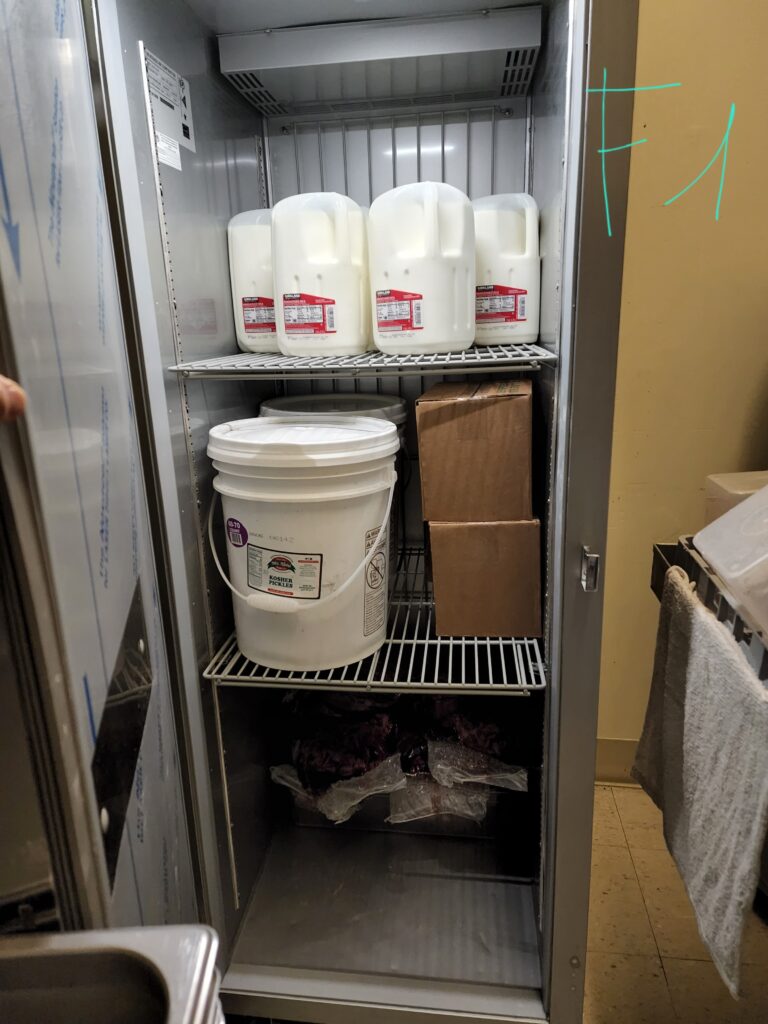

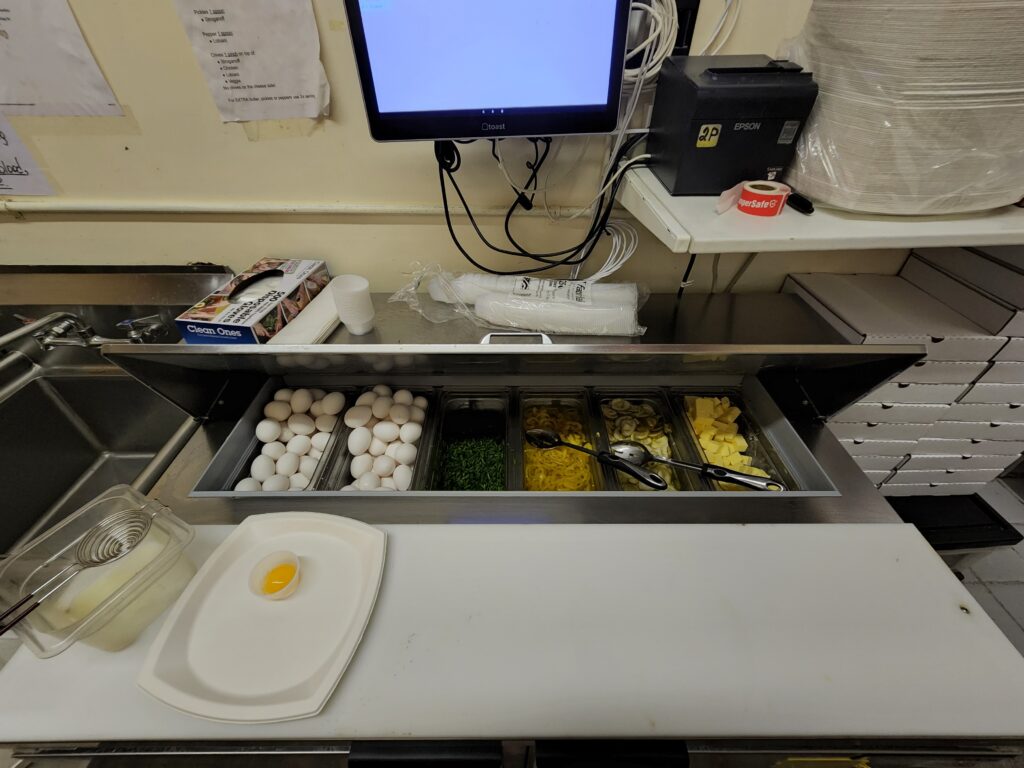

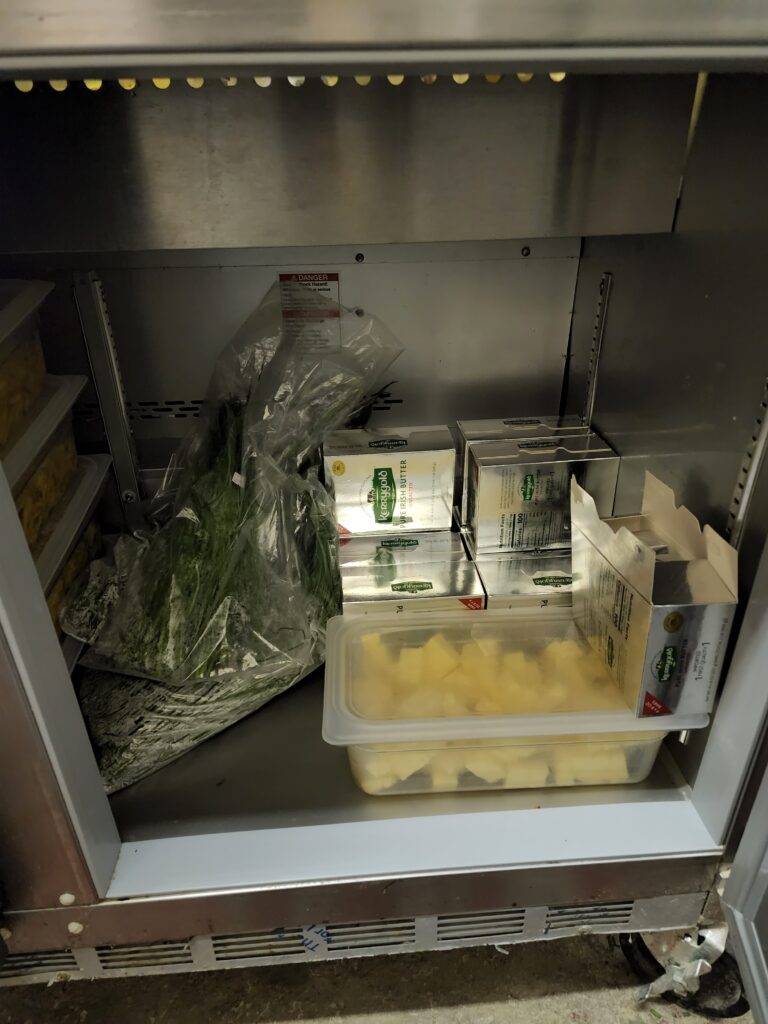

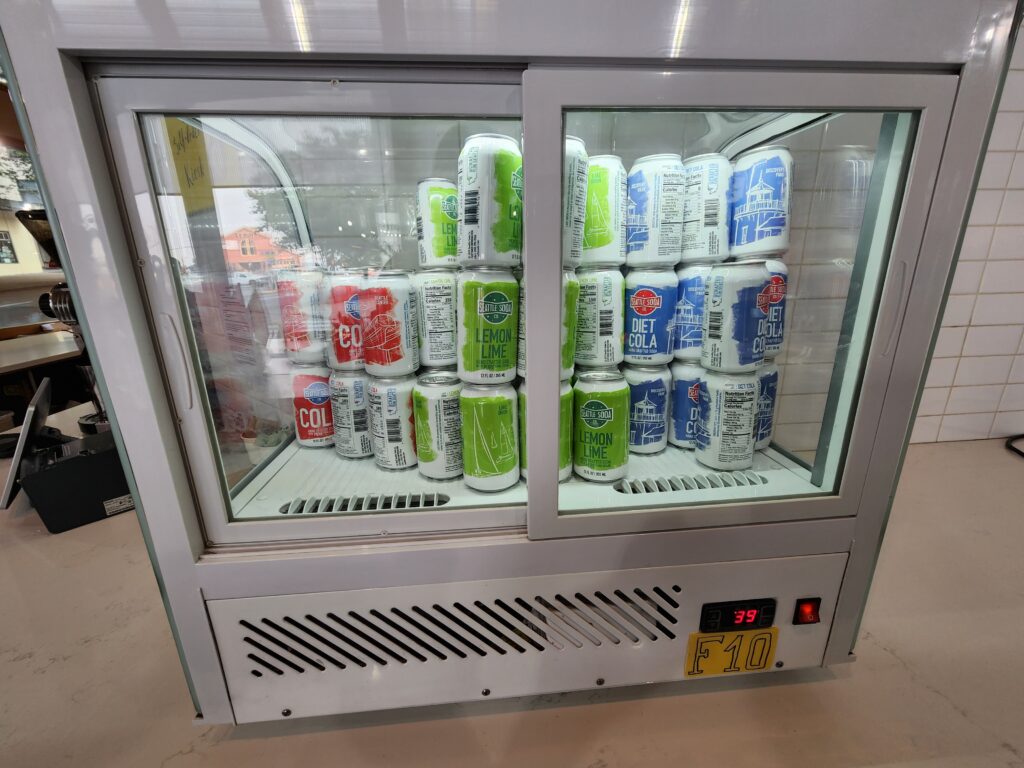

- Every team member should familiarize themselves and know where and how each item is stored, and what should be refrigerated.

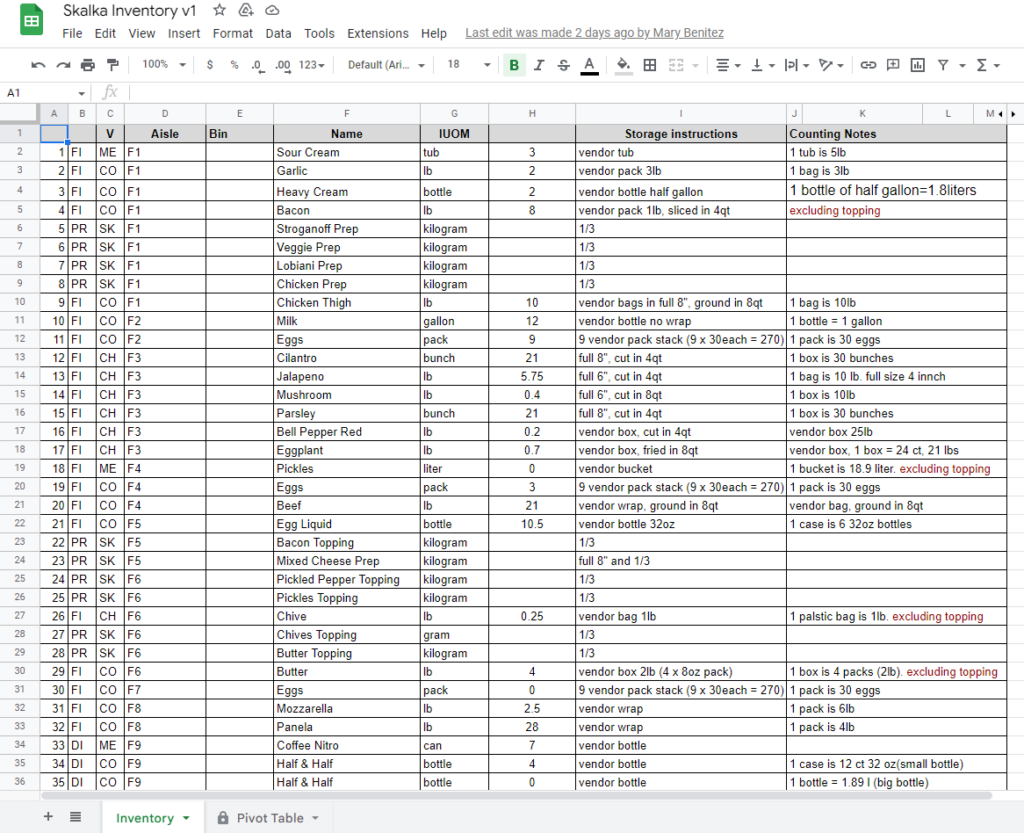

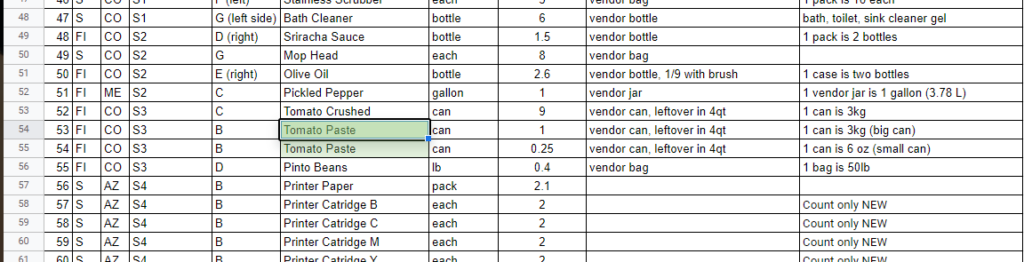

- In the restaurant, we used this spreadsheet named Skalka Inventory V1 in inventory: “https://docs.google.com/spreadsheets/d/11EcCrFfRz6h9zpFQJVrSThI_njftmsi0_uVw2PT_cro/edit#gid=0. There are quite a few columns. The second column indicates if the items are Food Ingredients (FI), Drink Ingredients (DI), Food Packaging (FP), Drink Packaging (DP), or Supplies (S). The column Aisle and Bin tells us where the items are located. S means shelf and F means fridge.

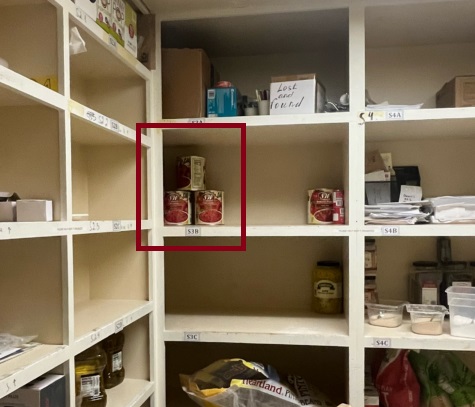

Let’s take Tomato Paste as an example. In the spreadsheet, tomato paste is located at shelve 3 bin B

In the picture below, you can see that it is located at S3B

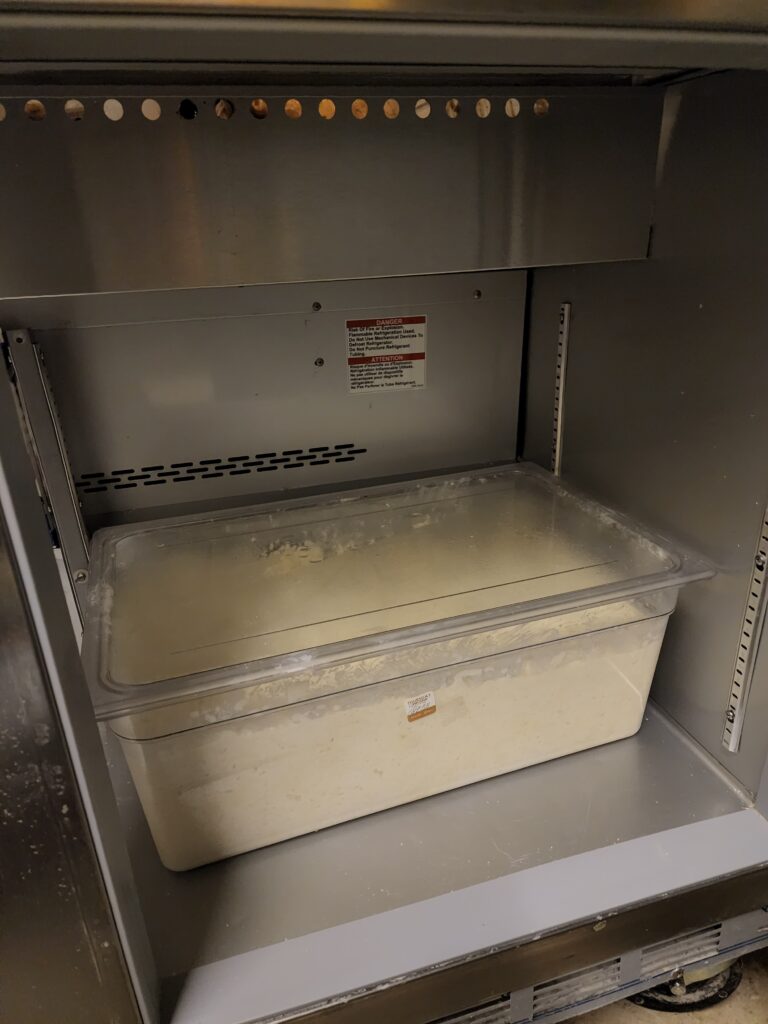

3. When a delivery arrives, we must store it on the shelves/fridges immediately. We order perishable items, and if they are not stored properly, they can spoil quickly and become unsafe to eat. This can lead to food waste and potential health risks for customers.

4. Every team member should know how to do FIFO (First in, first out). FIFO is “first in first out” and simply means you need to put the older foods in front or on top so that you use them first. This system allows you to find your food quickly and use it more efficiently. To ensure using food before expiration focus your choices on the FIFO principle by consuming the earliest purchased food items and whose shelf life is the shortest, first.

The FIFO procedure follows 5 simple steps:

- Locate products with the soonest best before or use-by dates.

- Remove items that are past these dates or are damaged.

- Place items with the soonest dates at the front.

- Stock new items behind the front stock; those with the latest dates should be at the back.

- Use stock at the front first.

5S Inventory

- Sort – Check all the areas, and look for products or items that are out of place, that are broken, dirty, or past due. Everything needs to be in the right place, if you don’t need it in that place, move it where it belongs. The goal of the Sort step is to eliminate clutter and clear up space by removing things that don’t belong in the area.

- Store – Everything needs to be organized and stored so that can be found easily in less than 30 seconds. The goal of this step is to organize the work area. Each item should be easy to find, use, and return: a place for everything, and everything in its place.

- Shine – This is the cleaning phase. Team members should not wait till lunchtime is over to start cleaning. All areas should be clean at all times. We should live by the motto’s keep it brand-new and leave it the same way you receive it. So if the floor is dirty, no matter which floor, you don’t wait till the Cleaning S shift is available, you clean your station right away, to avoid falls and contamination in other areas.

- Standardize – To keep the first three steps up and running through time, the standardized phase is key. Make sure to take pictures of the “ideal look” for every room, table, or storage area so that is easy to keep it always the same way.

- Sustain – The idea here is continuing commitment. It’s important to follow through on the decisions that we have made — and continually return to the earlier steps of 5S, in an ongoing cycle.